1. Обзор отрасли

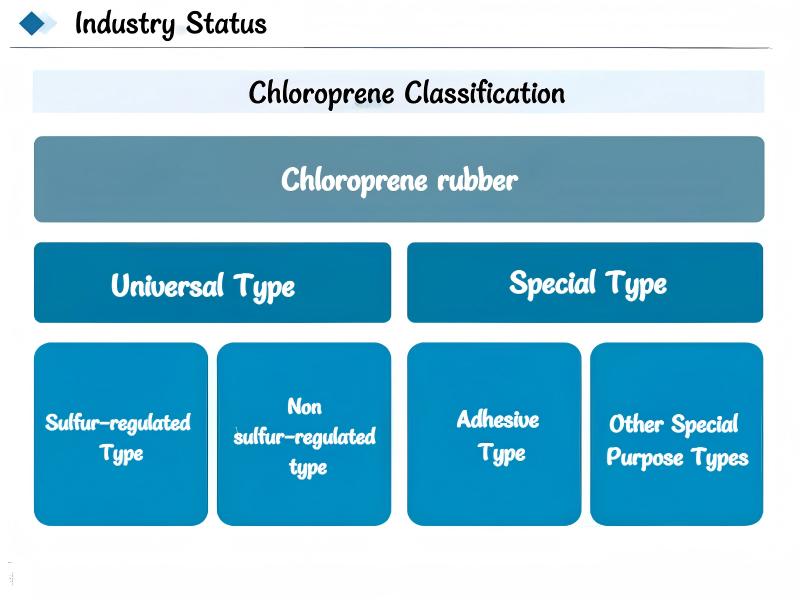

Хлоропреновый каучук (неопреновый латекс) — синтетический каучук, получаемый эмульсионной полимеризацией 2-хлор-1,3-бутадиена. Молекулярная структура хлоропренового каучука содержит атомы хлора, что обеспечивает ему хорошую стойкость к маслам, атмосферным воздействиям, пламени и химикатам. Он также обладает приемлемыми механическими свойствами и эластичностью. Компания DuPont впервые выпустила хлоропреновый каучук (CR) в 1931 году под названием «неопрен», что сделало его одним из первых синтетических каучуков, выпускаемых в промышленных масштабах. CR выпускается двух типов: общего и специального назначения, в зависимости от его свойств и применения.

2. Отраслевая цепочка

Производство хлоропренового каучука зависит от нескольких ключевых компонентов на начальном этапе. Это, главным образом, сырье и оборудование, необходимое для производства. Сырьё включает в себя сам хлоропрен, а также катализаторы, растворители, эмульгаторы, инициаторы, антиоксиданты и регуляторы. Что касается оборудования, то здесь вы найдёте реакторы для полимеризации, оборудование для эмульгирования, устройства для дегазации, упаковочные машины, устройства для очистки отходящих газов, системы очистки сточных вод и системы контроля безопасности. Хлоропреновый каучук находит своё основное применение в таких продуктах, как приводные ремни, уплотнительные ленты, шланги, резиновые листы, водонепроницаемые мембраны, клеи, антикоррозионные покрытия, кабельные оболочки и изоляционные материалы.

3. Статус отрасли

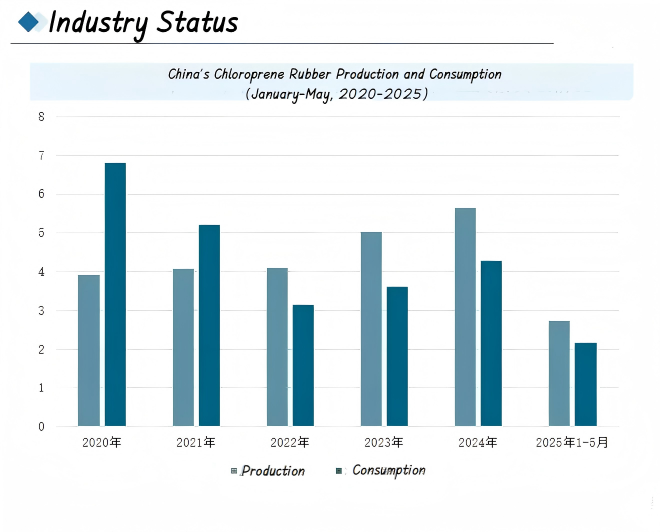

Китай является крупным производителем и потребителем хлоропренового каучука. Эта отрасль демонстрирует устойчивый рост благодаря растущему спросу со стороны автомобилестроения, строительства, электроники и производства медицинских приборов. С января по май 2025 года в Китае было произведено 27 200 тонн хлоропренового каучука, что на 15,80% больше, чем в прошлом году. Потребление этого материала достигло 21 700 тонн, что на 30,67% больше, чем в предыдущем году.

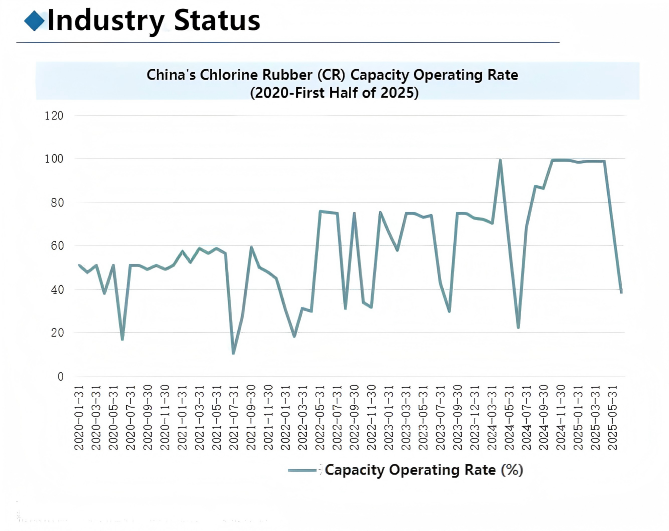

В июне 2025 года коэффициент загрузки китайских заводов по производству хлоропренового каучука составил 38,74%. Это на 31,63% меньше, чем в мае, но на 16,45% больше, чем в июне предыдущего года. Более низкий показатель типичен для июня, поскольку в этот период спрос обычно низок. Крупные отрасли, использующие каучук, такие как автомобилестроение и строительство, часто корректируют свое производство в это время. В частности, автомобильная промышленность столкнулась с более медленным спросом на детали из-за разговоров о меньшем количестве платежей за новые энергетические автомобили и снижения цен автомобильными компаниями. Строительный бизнес на юге Китая также использовал меньше гидроизоляционных материалов из-за сезона дождей, что означало меньшую потребность в неопреновом каучуке. Не помогло и то, что возникло больше проблем в мировой торговле, и то, что ЕС начал изучать, не продает ли Китай резиновые изделия слишком дёшево. Это сократило количество экспортных заказов и ещё больше ослабило спрос.

С января по май 2025 года Китай импортировал 6900 тонн неопренового каучука, что на 12,66% больше, чем за аналогичный период прошлого года. Стоимость этого импорта достигла 237 миллионов юаней, увеличившись на 12,05% по сравнению с аналогичным периодом прошлого года. За тот же период экспорт неопренового каучука из Китая составил 10 400 тонн, что на 10,36% меньше, чем в предыдущем году. Стоимость экспорта составила 283 миллиона юаней, что на 15,24% меньше, чем в прошлом году. В целом, зависимость моей страны от импорта неопренового каучука постепенно снижается: импорт увеличился с 19 600 тонн в 2020 году до 17 300 тонн в 2024 году, а экспорт, как ожидается, увеличится с 11 000 тонн в 2020 году до 26 400 тонн в 2024 году.

4. Тенденции развития отрасли

4.1 Ускоренная разработка высококачественных и специализированных продуктов

Ведущие предприятия, внедрив технологию реактора непрерывной полимеризации DuPont и объединив ее с самостоятельно разработанной технологией мгновенной дегазации неопренового латекса, успешно разработали такие высокотехнологичные модели, как Хлоропреновый каучук DCR1141 и Хлоропреновый каучук DCR2133Эти продукты обладают на 30% улучшенной термостойкостью и лидирующей в мире химической коррозионной стойкостью. Используя 77 лет накопленных технологий, компания создала первую в мире специализированную линию по производству неопренового каучука. Расширение областей применения в нисходящей цепочке дополнительно стимулирует процесс разработки высокотехнологичных изделий. Потребность в неопреновом каучуке растёт в транспортных средствах на новых источниках энергии, поскольку он используется для герметизации и изоляции аккумуляторных батарей. Кроме того, строительство базовых станций связи 5G увеличило использование высокотемпературного неопренового каучука в корпусе электронных компонентов в два раза.

4.2 Экологичное производство становится основной стратегией

Экологическая политика вынуждает отрасль ускорить экологическую трансформацию. Отрасль наращивает усилия по НИОКР в области создания высокопроизводительных и экологически чистых изделий из неопренового каучука.

4.3 Углубление глобальной схемы

Китайские компании, производящие неопреновый каучук, переходят от масштабного расширения к созданию стоимости. Ведущие предприятия получили сертификацию EU REACH и открыли научно-исследовательские центры в Германии, что привело к резкому росту продаж на европейском рынке. Стратегии международной конкуренции демонстрируют дифференциацию. Европейский и американский рынки фокусируются на преодолении технологических барьеров, захватывая высокотехнологичные рынки за счёт производства продукции по индивидуальным заказам (например, медицинского неопрена). На политическом уровне инициатива «Один пояс, один путь» способствовала росту спроса в странах-участницах, значительно усилив международное влияние отрасли.

Веб-сайт: www.elephchem.com

Вотсап: (+)86 13851435272

Электронная почта: admin@elephchem.com

JiangSu ElephChem Holding Limited, профессиональный эксперт рынка Cхлоропреновый каучук иПоливиниловый спирт (ПВС) с прочным признанием и превосходными производственными мощностями, соответствующими международным стандартам.